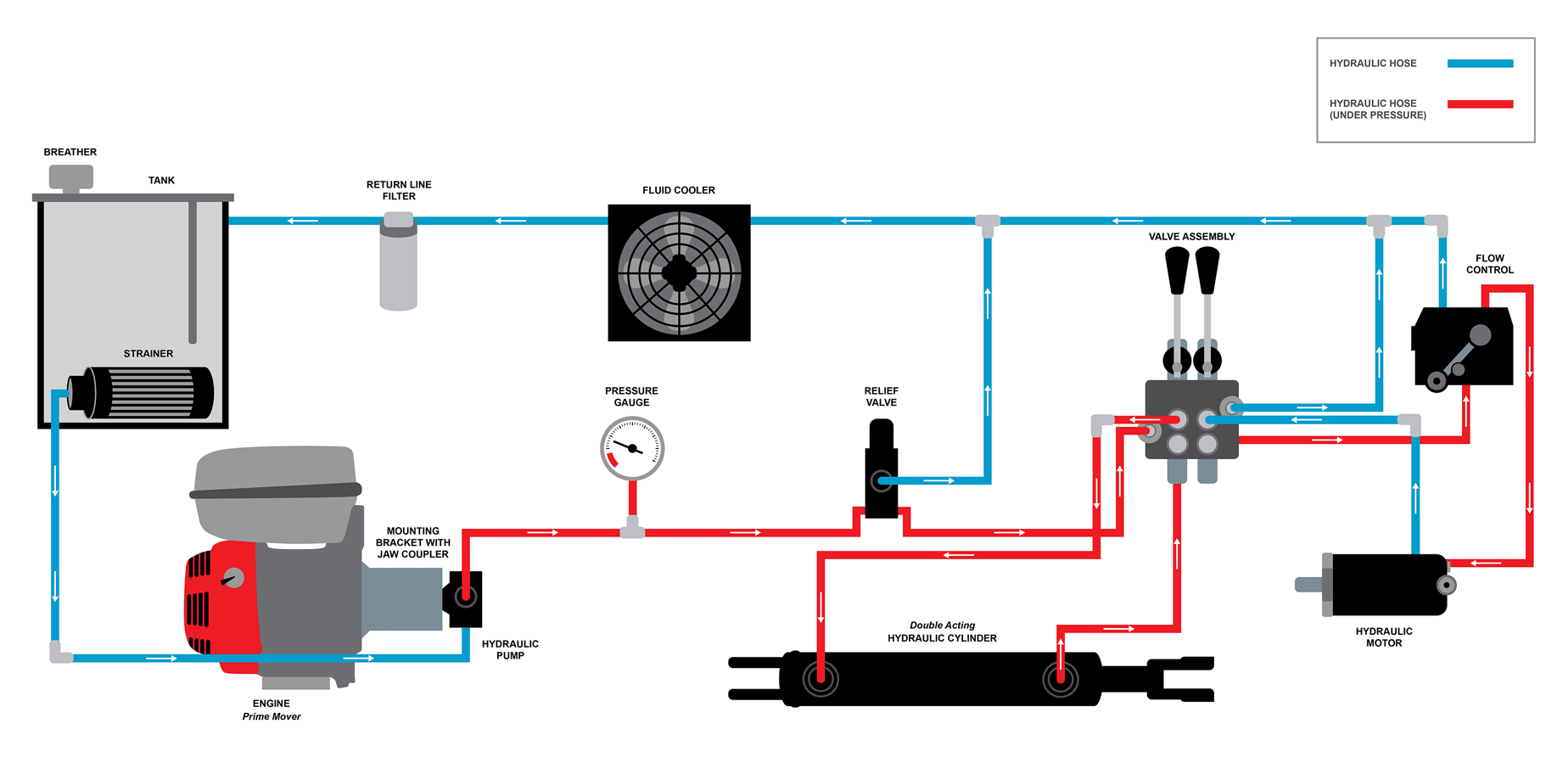

Components of a Hydraulic System

A hydraulic system is composed of various components to keep the fluid under the desired pressure, clean, and moving in the right direction. Below is an overview of those components

Reservoir Tank

The hydraulic tank acts as a reservoir, holding fluid, and is connected directly to the pump. It allows air bubbles to dissipate and contamination particles to settle, as well as allows the oil to cool while it is not circulating. A vented filter cap controls air flow, and a filter or strainer keeps contaminants out of the hydraulic fluid.

Pump and Engine

The hydraulic pump moves liquid from the reservoir tank through the system driven by an engine. Pump designs are typically two-stage, PTO or manual hydraulic, while the engine can be gas, diesel or electric depending on access to power, the horsepower needed and mounting style.

Pressure Gauges and Relief Valve

Once liquid is circulating, gauges can be used virtually anywhere in the system to monitor pressure. In addition, a relief valve controls the fluid pressure that powers the hydraulic cylinder; excess fluid is returned to the reservoir tank. This prevents pressure build-up and potential damage to equipment.

Valve Assembly

The hydraulic valve assembly controls the direction, pressure and flow rate of fluid through a hydraulic circuit. It regulates the speed of motors and movement of cylinders. Directional control valves are most common, controlling fluid flow from the pump to the cylinders and other system components.

Cylinder

A hydraulic cylinder is an actuator that creates linear movement by converting hydraulic energy back to a mechanical movement – so it is the component that drives the work performed by mobile equipment. Cylinders can be used to lift, push, pull and press loads that require exceptional force.

Motor

Similar to cylinders, motors are actuators that converts hydraulic pressure and flow into movement, but it’s converted into torque and angular displacement (rotation) rather than linear motion. The amount of pressure and displacement of a motor will determine how much torque is produced while the amount of flow will determine the speed.

Flow Control Valve

The purpose of a flow control valve is to regulate the flow rate to motors and cylinders, thereby regulating the speed of those components.

Fluid Cooler

This unit removes the excess heat generated from the hydraulic fluid and helps to keep the temperature within a limited range before returning to the reservoir. Without proper cooling, the hydraulic system could overheat, causing component damage. Keeping the system properly cooled also extends hydraulic fluid life.